- The importance of shank adapter manufacturers extends beyond their products. They also provide technical support, guidance on proper usage, and maintenance advice, fostering a collaborative relationship with their clients. Their expertise is invaluable in ensuring that these adapters perform optimally in often harsh and demanding environments.

- When choosing a pneumatic jack hammer, there are several factors to consider. The most important factor is the size and weight of the hammer, as this will determine how easily it can be transported and operated on the job site. Other factors to consider include the impact energy of the hammer, the air consumption rate, and the noise level.

- Efficiency and safety are paramount concerns when using rock drill tools for tunnel drilling. Proper maintenance and inspection of the equipment are essential to prevent malfunctions and ensure smooth operation. Regular checks on drill bits, drilling machines, and support equipment are necessary to identify any potential issues and address them promptly. Training for operators is also crucial to ensure that they possess the necessary skills and knowledge to operate the equipment safely and effectively.

- Button bit for rock drilling is a crucial component in the process of drilling through hard rock surfaces. This type of bit consists of a series of small, hard buttons or inserts that are strategically placed on the surface of the bit. These buttons are usually made from tungsten carbide, which is known for its durability and ability to withstand high temperatures and extreme pressure.

- Moreover, this material demonstrates excellent thermal and electrical insulation properties, adding another layer of protection against temperature fluctuations and electrical currents

- Another significant advantage of chisel drill rods is their durability

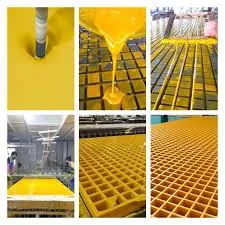

As the name suggests, molded grating is created on the mold; whereas pultruded grating is created by combining the pultruded profiles in the shape of grating. Molded fiberglass grating is a combination of thermosetting resin with fiberglass roving to create a strong one piece panel.

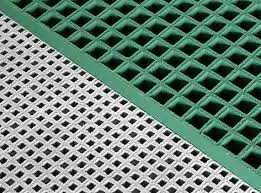

Food Processing: Used in food processing facilities due to its corrosion resistant and easy-to-clean properties. USDA/CFIA accepted and anti-microbial formulations provide additional benefits.

FRP gratings are commonly molded using high-strength fiberglass reinforcement materials along with resin and other additive agents to enhance product quality. Molded FRP gratings find widespread use across various industrial sectors such as power generation, waste processing, oil refining, mining, and more. Additionally, these gratings are increasingly utilized in commercial settings as interior and exterior materials, including drainage systems, fencing, building facades, ceilings, and others.

Moreover, their energy-efficient operation reduces fuel consumption, contributing to a lower carbon footprint and a more sustainable approach to construction and mining Moreover, their energy-efficient operation reduces fuel consumption, contributing to a lower carbon footprint and a more sustainable approach to construction and mining

Moreover, their energy-efficient operation reduces fuel consumption, contributing to a lower carbon footprint and a more sustainable approach to construction and mining Moreover, their energy-efficient operation reduces fuel consumption, contributing to a lower carbon footprint and a more sustainable approach to construction and mining portable rock drill.

portable rock drill. By positioning the camera closer to the subject, photographers can capture more detail and create a more immersive viewing experience for their audience By positioning the camera closer to the subject, photographers can capture more detail and create a more immersive viewing experience for their audience

By positioning the camera closer to the subject, photographers can capture more detail and create a more immersive viewing experience for their audience By positioning the camera closer to the subject, photographers can capture more detail and create a more immersive viewing experience for their audience extension support rod.

extension support rod. heavy duty jack hammer price. Well-established brands with a history of quality products and excellent customer support often command higher prices. This is because consumers trust that they are purchasing a reliable tool backed by a company committed to providing satisfaction and assistance if needed.

heavy duty jack hammer price. Well-established brands with a history of quality products and excellent customer support often command higher prices. This is because consumers trust that they are purchasing a reliable tool backed by a company committed to providing satisfaction and assistance if needed.

Fiberglass pultruded grating also facilitates the direct flow of car wash water into the trench. There is no water in the car wash working position, and the FRP grille has a strong load-bearing capacity. It can be applied in car washes, urban greening, shipyards, and sewage treatment plants.

pp frp tank. The non-reactive nature of FRP ensures that the tank retains its integrity and performance over time, even in the face of extreme conditions.

pp frp tank. The non-reactive nature of FRP ensures that the tank retains its integrity and performance over time, even in the face of extreme conditions. The fiberglass material used in these cars can be easily molded into different shapes and designs, giving owners the freedom to create a unique and eye-catching vehicle The fiberglass material used in these cars can be easily molded into different shapes and designs, giving owners the freedom to create a unique and eye-catching vehicle

The fiberglass material used in these cars can be easily molded into different shapes and designs, giving owners the freedom to create a unique and eye-catching vehicle The fiberglass material used in these cars can be easily molded into different shapes and designs, giving owners the freedom to create a unique and eye-catching vehicle frp car. Additionally, the plastic components of frp cars can be easily painted and modified, allowing for endless customization options.

frp car. Additionally, the plastic components of frp cars can be easily painted and modified, allowing for endless customization options.